ASPC’s Lean Vertical Integration Strategy

Some surprising benefits of ASPC’s Lean Vertical Integration Strategy

ASPC’s Lean Vertical Integration Strategy allows us to provide quicker deliveries of high-quality products manufactured with a lower cost structure by:

- Eliminating the quality damage & additional processing time incurred from additional handling and freighting parts to various outside suppliers

- Eliminating the additional processing time incurred with shipment & queue times at various outside suppliers

- Eliminating the finger pointing of “who is to blame” when quality or delivery issues arise

- Eliminating the additional costs & markups of the added various outside suppliers

- Eliminating the additional cost of handling & shipments to various outside suppliers

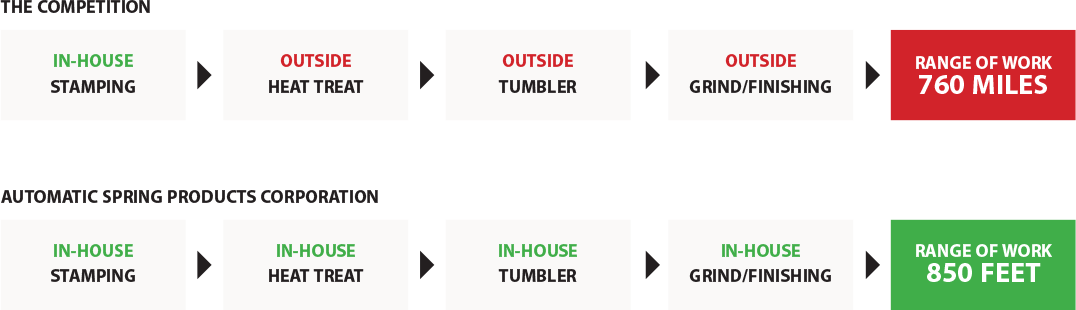

ASPC’s Lean Vertical Integration Strategy in action

One of our competitors who manufactures ground precision shim/spacers found that their product traveled about 760 miles to complete all the required manufacturing steps.

Here’s what our competitor was doing.

They would stamp the product, then send it to an outside heat treater, then to an outside tumbler, then to an outside grind shop and finishing shop….

As you can imagine, they had significant issues with time, distortion, and variables in handling.

On the other hand, ASPC’s Lean Vertical Integration Strategy allows us to complete the same required manufacturing steps in just 850 feet!

COBOT’s at Work

// Company

Automatic Spring Products Corporation maintains a strong commitment to adopting new and emerging technologies. We have introduced collaborative robots into...

// Company

COBOT’s at Work

Heat Treat Today Magazine recognizes Aniket Maske

// Featured Article

9/14/22

// Featured Article

Heat Treat Today Magazine recognizes Aniket Maske

ASPC earns GM Supplier Quality Excellence Award for 2019

// award excellence GM quality supplier

Dear Supplier, I would like to congratulate you on your outstanding performance in 2019! You are receiving this letter because...

// award excellence GM quality supplier

ASPC earns GM Supplier Quality Excellence Award for 2019

New Clip Design for National Pants Hanger Company

// In-House Finishing

A national hanger manufacturer came to Automatic Spring Products Corp. to request help in developing a spring clip application for...

// In-House Finishing