ASPC’s Lean Vertical Integration Strategy

At ASPC, we are dedicated to engineering new and innovative ways to provide the best products at reasonable prices to our customers.

And one of the main ways we do this is with our Lean Vertical Integration Strategy.

Learn more about what this strategy is, the benefits of lean manufacturing, and how we’ve used it to help our customers in today’s post.

The basics of ASPC’s Lean Vertical Integration Strategy

Our strategic business model is built on over 60 years of manufacturing and experience and, in recent years, driven by the core ideas and principles of lean manufacturing.

Per the Lean Enterprise Institute: “The core idea [of lean manufacturing] is to maximize customer value while minimizing waste. Simply, lean means creating more value for customers with fewer resources…. The ultimate goal is to provide perfect value to the customer through a perfect value creation process that has zero waste.”

We’ve used the concept of lean manufacturing to develop ways to better serve our customers, reduce waste, make our processes more efficient, and be more environmentally sustainable.

ASPC’s Learn Vertical Integration Strategy is defined by our in-house manufacturing processes, which include:

- Prototyping, tool design & build, and metal-forming

- Austemper & oil quench heat treating & heat setting

- Deburring, shot peening, zinc phosphating & nylon coating

- Precision double-disk grinding, welding & assembly

By performing manufacturing processes like these in-house, we can reduce the process time and regulate each part to ensure the highest quality before shipment.

Some surprising benefits of ASPC’s Lean Vertical Integration Strategy

ASPC’s Lean Vertical Integration Strategy allows us to provide quicker deliveries of high-quality products manufactured with a lower cost structure by:

- Eliminating the quality damage & additional processing time incurred from additional handling and freighting parts to various outside suppliers

- Eliminating the additional processing time incurred with shipment & queue times at various outside suppliers

- Eliminating the finger pointing of “who is to blame” when quality or delivery issues arise

- Eliminating the additional costs & markups of the added various outside suppliers

- Eliminating the additional cost of handling & shipments to various outside suppliers

ASPC’s Lean Vertical Integration Strategy in action

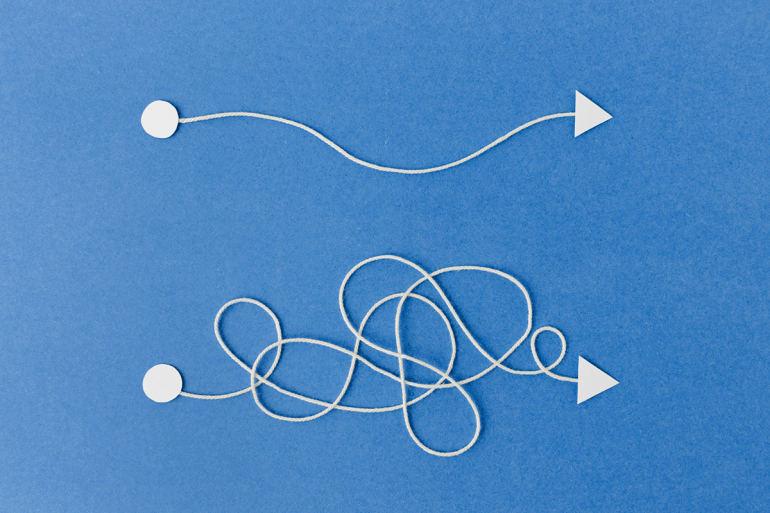

One of our competitors who manufactures ground precision shim/spacers found that their product traveled about 760 miles to complete all the required manufacturing steps.

Here’s what our competitor was doing.

They would stamp the product, then send it to an outside heat treater, then to an outside tumbler, then to an outside grind shop and finishing shop….

As you can imagine, they had significant issues with time, distortion, and variables in handling.

On the other hand, ASPC’s Lean Vertical Integration Strategy allows us to complete the same required manufacturing steps in just 850 feet!

Curious to know more?

Contact us and learn how our Lean Vertical Integration Strategy can save you time, money & headaches!

Notice: Undefined variable: maincat in /var/www/html/wp-content/themes/asp-child/single.php on line 12

Notice: Trying to access array offset on value of type null in /var/www/html/wp-content/themes/asp-child/single.php on line 12

Notice: Trying to get property 'slug' of non-object in /var/www/html/wp-content/themes/asp-child/single.php on line 12